Exploring Mechanical Seal Innovations at ACHEMA 2024

At AshishSeals, we are constantly looking for ways to enhance

ISO 9001 : 2015 Certified Company

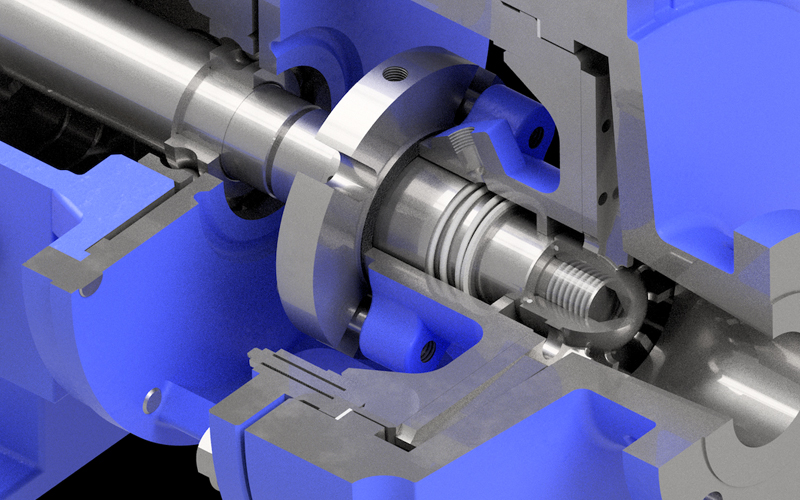

Ashish Seals is ISO 9001 : 2015 Certified Company, based in Mumbai India. Our intense knowledge and vast experience have supported the company to acquire the eminent position among the most reliable Manufacturer & Exporter of Mechanical Seal in entire India.

With our consistent performance and superior quality products, we have established ourselves as a renowned company catering to our clients with varied precision mechanical seal solutions. Our state-of-the-art production machines assist us in developing flawless series of products. They also help us to meet bulk orders within the specified time, without compromising with the quality. Our profound infrastructure facilities with machinery and allied tool facilitate helps us in meeting the complete product needs of our clients successfully. The expertise and in-depth knowledge of our team assists us in carrying out designing and manufacturing requirements.

PS37

PS37 PS39

PS39 PS35

PS35 DS71

DS71 RJRU90

RJRU90 BS11

BS11 TSP100

TSP100 AS91

AS91We are a growing company involved in providing mechanical sealing solutions for chemical process industry and other industries.

We conduct stringent quality checks starting from the procurement of raw materials till the delivery of the finished products & After Sales customer Satisfaction.

Carbon, Ceramic, Silicon Carbides, Tungsten Carbide, Stelite, Ptfe, Gft, Cft, Viton, Epdm, Neoprene, Ttv, Encapsulated & Other Non Metals, Check of rough dimension, Vacuum testing, High pressure testing, Hardness testing, Check for any surface cracks.

Shaft, Sleeves, Gland Plates, Retainer, Collar, Screws, Springs, Pins, Seal Housing And Seal Faces, Bore checking with plug gauges, Dimensional check up, Ensure required surface finish, Monochromatic light band inspection, Parallelism of seal faces.

Stainless Steel, Alloy Steel, Hastalloy, Monel, Lacrolloy, Ni-Resist, Ms, En, Brass, Bronze, Phosphorus Bronze & Other Metals, Spark testing, Dimensional checking, Ultrasonic testing, X ray & radiography, Check for any surface cracks.

Marking on components, Ultrasonic cleaning of all parts, Flatness inspection of seal faces, Compression load testing of springs, Assemble the seal with sleeve and housing, Static pressure testing, Running trial on dummy shaft, seal & test reports.

Ultrasonic testing of all components, Flatness checking of seal faces,Co-relate dimensions with assembly drawing, Load testing of spring/bellows, Certification of material test reports,Dimensional check up of custom made components.

All components packed in tissue paper & air bubble, Preparation of the packing slip, Operating and maintenance instructions, Labeling with seal data.

Making available world class Chemical Process Pumps & Mechanical Seals to suit different clients has been possible with our strong sense of integrity, a knack for improvisation and exemplary quality equipment.

Ashish Seals can custom engineer seals to your exact specifications.

Our technicians carefully inspect each seal during each step of the process.

All of our seals are pressure tested after final assembly to assure quality.

Our Happy Clients

Team Member

Years Experience

At AshishSeals, we are constantly looking for ways to enhance

At Ashish Seals, we are constantly seeking opportunities to expand

Ashish Seals, a leading Indian manufacturer and exporter of mechanical

Maintains the reliability of the installed systems by preventing fluid

info@ashishseals.com

sales@ashishseals.com

+91 916 770 9460

09:00 AM - 07:00 PM